The outline of the progress

The new design project of an innovative graphene bulb based on technology patented by the National Academy of Sciences in Wrocław is now available. The technology implemented in the light bulb allows induction of light in the visible spectrum via the use of a laser beam with a wavelength in the infrared (IR) range. In the article, we will also share the market analysis and many interesting details about the project. The aim of the project is to create a prototype of a graphene bulb based on an original industrial design.

The first stage of the graphene bulb design project consisted of finding technical solutions that would enable the construction of a new product in a patented technology, which thus far had not been used for commercial purposes. Specialists from various fields, including engineers specializing in laser technology, were involved in the project. The project turned out to be quite a challenge as it was impossible to use components available on the market. After constructing a dedicated laser and estimating the measurements of the target product, it was time for a concept design.

The characteristic features of the graphene bulb design are the possibility of non-contact work in relation to the energy supply and the lack of electrodes. The selection of elements (such as a battery-powered laser) and placing a graphene pellet in a closed medium in an inert gas are sufficient to obtain the illumination of white light (corresponding to the spectrum of sunlight). Such functioning of the light bulb enforces its mechanical, electrical and optical construction, as well as the construction of the entire chain of subsystems that support it. It should be assumed that a graphene bulb, an infrared laser and a laser power supply are sufficient to implement a white light source. However, the design problem turns out to be the new architecture and design of the product, which will enable the use of the new product as a typical light bulb with a thread, which can be screwed into a 230V power source like any other bulb available on the market for the convenience of consumers.

Coming back to the core elements of the project, the laser is responsible for generating the energy in the light bulb. The laser wavelength is between 800 - 1100 nm, which corresponds to the wavelength of infrared radiation. The most optimal laser wavelength, which causes the induction and emission of light by graphene, is in the range of 808 - 980 nm, while the optimal laser power should be somewhere between 1.0 - 2.0 W. Interestingly, graphene could glow even more were it irradiated with laser in several places (e.g. at three different points), but such a solution for the prototype was rejected due to the inability to split a singular laser beam and too great technical difficulties that would result from the implementation of three lasers to one light bulb, which would be too costly.

Materials selection policy

The main goal of the materials selection policy is to describe the list of materials that are necessary to manufacture a new product, along with the list of suppliers and the criteria for assessing the quality of materials and their application. However, for the duration of project design realization, it is difficult to assess what materials and components will eventually be used in the production of the new merchandise, especially it if were to be a larger scale production (this would involve a change in technology and requires more in-depth preparation, as well as equipping the machines for the production of the graphene bulb).

The presented materials policy is applicable for the production of individual light bulbs. Its specification results from the current technical capabilities, available materials, expertise, specific budget and time for project implementation. In the case of bulb production based on manual assembly of the bulb and specialist equipment (and assuming that a larger volume will reduce production costs), one should expect the unit cost of producing a bulb of around PLN 2,000. Such costs far exceed the production costs of, for example, LED bulbs. LED light bulbs with graphene, which give a slightly warm light (2700K, 800lm), are available on the market at a price of about 30-40 PLN. The difference is that they are only a refinement of LED technology with the addition of graphene. The spectrum of the light does not change, unlike the IR-induced graphene which gives the spectrum of white light. The use of the keyword "graphene" in the names of LED bulbs may result in individual customers not knowing the difference between the bulbs, nor will they be eager to spend so much money. Taking that into consideration we can come to the conclusion that at the moment the only viable application for the new graphene bulb are specialist purposes. An alternative solution could be use of cheaper components for the laser construction (which will allow for high power above 1000 mW) or the use of other technology to induce graphene, e.g. LED light, if it is possible. This will reduce the production costs of the bulb while maintaining its qualities and white light emission properties.

Graphene emits light much better under a reduced atmospheric pressure. Therefore, in a vacuum or in an inert gas atmosphere, we can observe a few hundred or even a thousand times more effective light. The form of graphene resembles a pellet that is placed, for example, on a glass pin protruding from the inside of a glass ball filled with an inert gas. The applied material selection policy and waste management should be consistent with the sustainable development strategy. At the time of the design project realization, the materials necessary for the production of graphene bulbs constitute a large price barrier for consumers, therefore the production of a new product should be based on individual and dedicated orders, until the production technology is developed and the economic efficiency is improved. The main obstacle for the implementation of this material selection policy is the high cost of producing a graphene bulb. The cost is dependent on the price of the laser with power above 1 W, emitting a spot-focused infrared beam (over PLN 3,000). Another problem is the protection of eyesight against the radiation, which passes through the lamp shade (infrared-absorbing glass has a green-blue color, distorts the color of light, and, most importantly, specialized transparent infrared-absorbing glass is expensive - costs about PLN 2,000 per bulb). Another obstacle is the production preparation for a new, unusual and innovative industrial design that will catch consumers' eye. During the implementation of the design and development of the prototype, it is not possible to create a strict material policy and selection for the production of the bulb due to the fact that this is a very early stage of product development and some changes might be necessary in future.

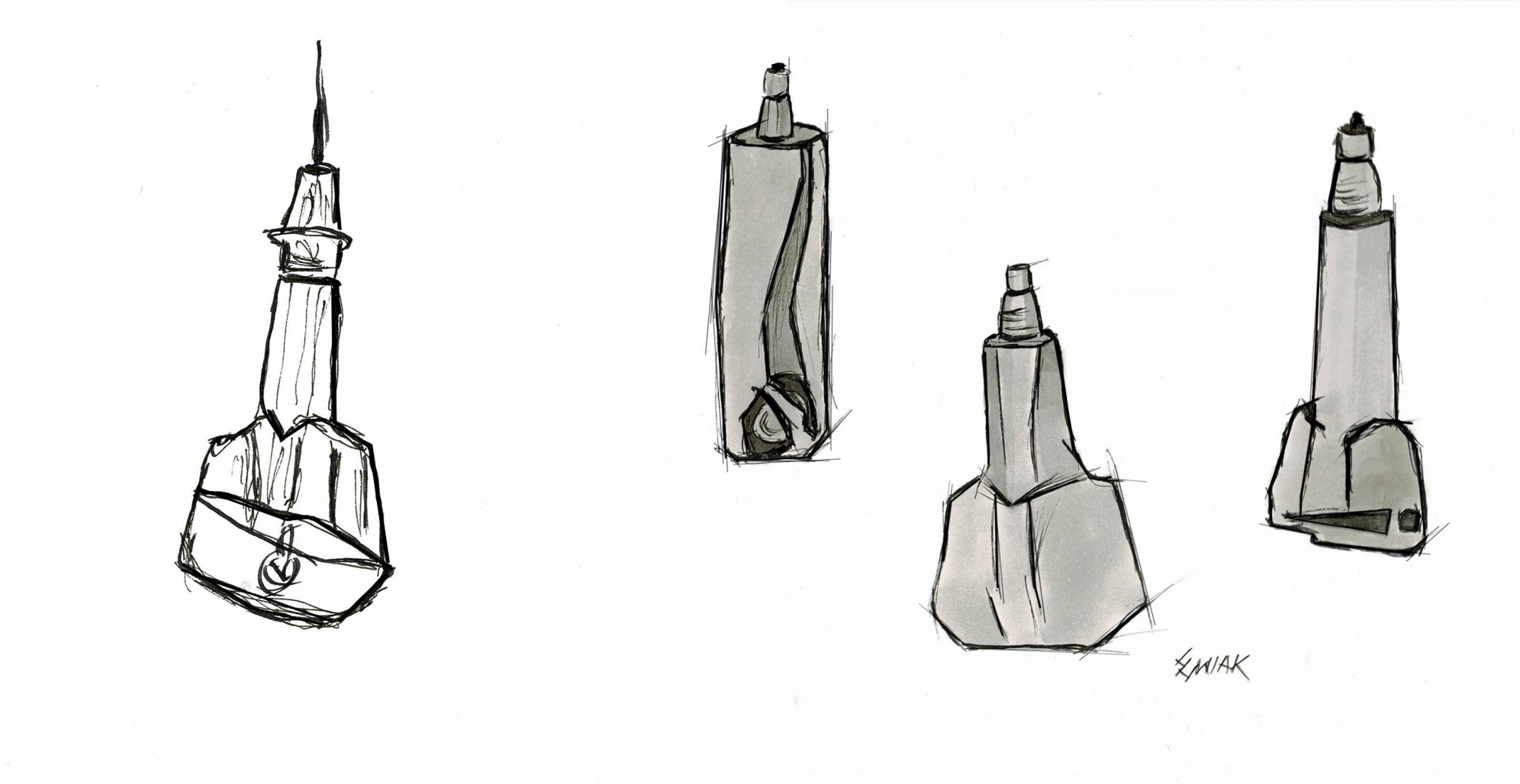

Concept sketches

Concept sketches

The light bulb's design

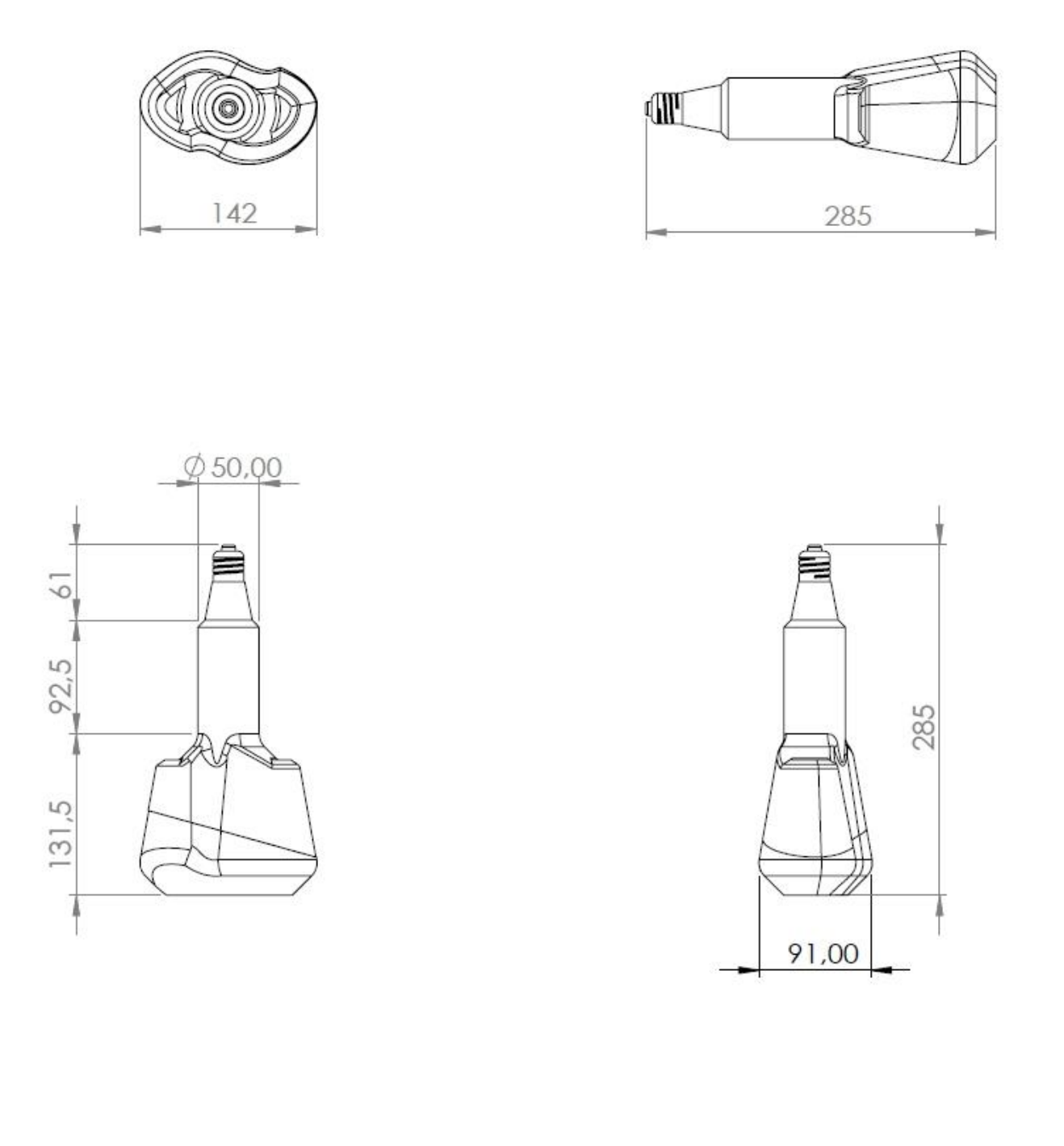

The recommended vision for the design is somewhat futuristic due to the proposal of an asymmetrical lamp shade. The design is industrial, but with a touch of artistic spirit, yet the most important quality is the minimalistic result, thanks to which it can be applied universally.

Round shapes improve ergonomics of screwing in and unscrewing the bulb. The innovative graphene bulb is a product dedicated to the specialist industry. By using the IR-graphene technology patent, it is a testimony of cooperation between science, designers and business. It has a modern, but partially conservative design. The lampshade will be partially transparent. What do you think about this design?

The first graphene light bulb prototype's measures are 28,5 x 14 cm. Due to its size, it is planned to systematically reduce it in later production stages. This procedure can be achieved by the use of smaller elements in the laser construction.

As you can see, our experts are going the extra mile to achieve the best results. There will be more updates on the progress soon!

50 032 624

50 032 624